Virtual reality training in pharma: just a headset away?

Posted: 14 February 2023 | Dr Blanka Szulc (University of Kent), Dr Stephen Hilton (UCL School of Pharmacy) | 1 comment

Here, Virtual Reality experts UCL’s Steve Hilton and University of Kent’s Blanka Szulc reflect on key developments in the use of virtual reality in an academic setting and its outlook for the future.

The COVID-19 pandemic led to an unparalleled paradigm shift in the use of and the incorporation of new technologies into our workflows. This was particularly apparent in academia and the pharmaceutical industry, where we have seen words such as Teams and Zoom becoming part of our new lexicon of language for meetings. Now we reach for these types of online meetings without a second thought, due to the clear productivity benefits they provide over real in-person meetings.1

However, notwithstanding the widespread use of these digital platforms and their advantages for online learning, they still cannot fully replace the gold standard of in-person scientific equipment training. Due to the challenges of the pandemic in blocking in-person interactions, we sought to explore the use of virtual reality training for this deficit. We followed our experience of 3D printing in laboratories, where we had seen the benefits of being able to realise physical objects from computer aided designs (CAD) designs in a matter of hours.2-5

We quickly realised that the same CAD models we had developed for 3D printing such as molecular models, could easily be viewed in the same way in virtual reality, via a VR headset but without needing to 3D print the same object.5

We quickly realised that the same CAD models we had developed for 3D printing could easily be viewed in the same way in virtual reality, via a VR headset “

Our early forays into the use of VR technology and hardware allowed us to quickly realise this vision, via the use of some excellent commercial programs and providers. However, these were often static builds that could not be modified once purchased. Their ongoing connection/subscription costs and our innocence in the use of VR blunted some of the initial early enthusiasm.5

As such, we sought to understand the technology from the ground up – to design and develop our own VR-based software solution, allowing us to quickly make changes where required. Our approach focused on the creation of a digital twin of our laboratories, where laboratory equipment could be virtualised and placed in a VR model of the lab. This would allow lab staff to rapidly observe the benefits of this technology, as they were able to see the real-world version of the lab and then transition immediately to the VR version by wearing a VR headset. Having realised this vision, we were then able to clearly explain its benefits to others via in-person visits followed by digital VR training. 6,7

An interactive digital-twin laboratory environment

While many VR programs focus on single user interactions and experiences, we wanted to be able to meet others in VR and show them the digital twin version of our lab and the technologies that we had developed.

One benefit that we derived from this approach was the early realisation of school ‘visits’ to our laboratories during the latter stages of the pandemic. This was made possible by sending the headsets or software to a school, where students could join remotely via VR and visit our laboratory and interact with the equipment inside.

Any student can easily visit university laboratories and interact with advanced equipment by simply placing a VR headset on”

This was an eye-opening first step in this technology. It is an amazing opportunity for the future in terms of social mobility, as any student can easily visit university laboratories and interact with advanced equipment by simply placing a VR headset on. In this manner, we were able to have two schools ‘visit’ our laboratories in the space of an hour. Previous visits would have taken several days of planning and expense for the schools involved. Multiple days of visits would only benefit about 10-15 students at most, versus 50-60 via the use of VR in little over an hour of interaction.8

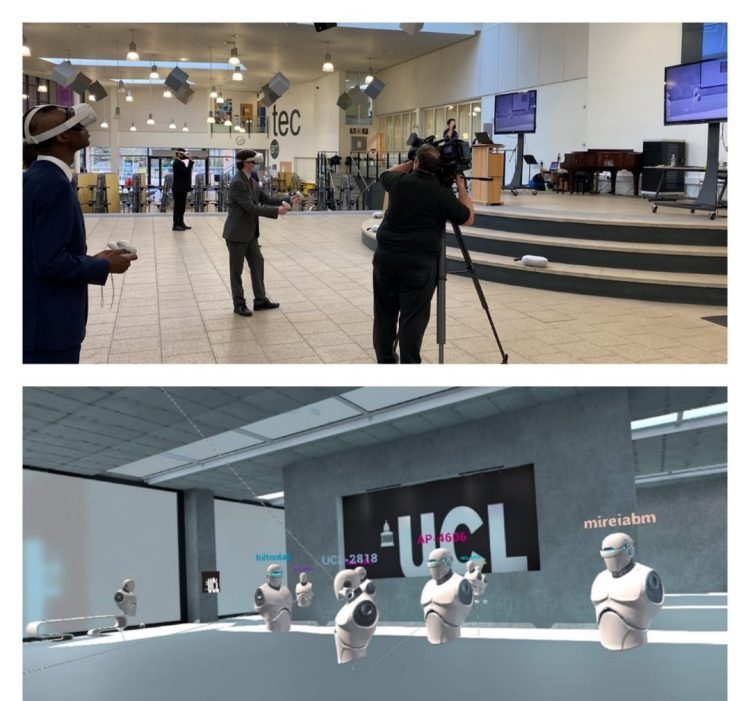

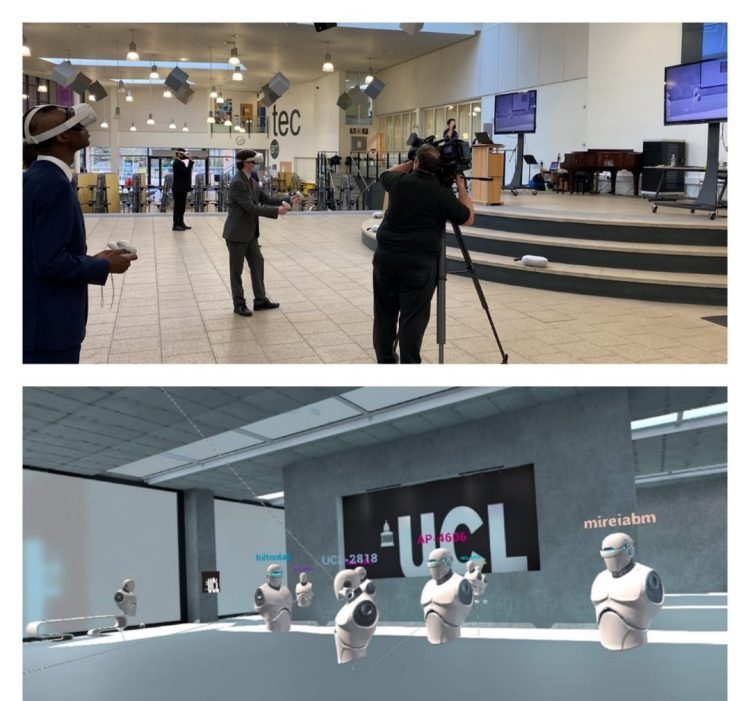

Figure 1: VR Based Outreach: Top) Students using VR headsets. Bottom) View of students from inside VR (Photo credit: UCL).

HPLC training using VR

Following this early success, we next sought to expand our training to the undergraduate curriculum as we were able to witness the benefits that VR provided. One area where VR had a clear use-case opportunity was in the area of High Performance Liquid Chromatography (HPLC) training. Classic undergraduate training on these systems involve little or no in-person training, due to the high costs of these machines. As such, students are simply shown the machine in groups from a distance and are never normally allowed to touch it, and given handouts instead.9

One area where VR had a clear use-case opportunity was in the area of High Performance Liquid Chromatography (HPLC) training.”

We envisaged an approach whereby students could simply put on a VR headset and then interact with the machine in the same way as real life. However, by using VR and a CAD based version, we would be able to provide each student with their own HPLC. We designed a CAD version of an HPLC, made it interactive and designed a class around this, enhancing current undergraduate practicals. We were able to showcase this to over 300 students across two Universities. Feedback was overwhelmingly positive and this HPLC training has now become a core part of the undergraduate curriculum.

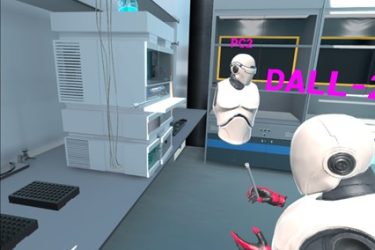

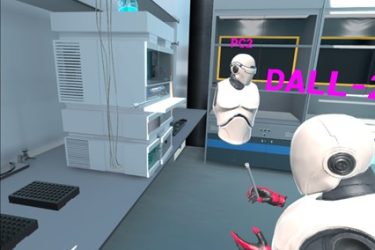

Figure 2: Virtual reality digital twin version of the HPLC in use.

After using VR with a larger audience, we realised three key points from our experience. First, we initially decided to not use personalised avatars and elected to employ robotic avatars (shown in Figure 2) due to time constraints and simplicity. However, in hindsight, this has been a boon for persuading students to interact. For in much the same way that most students do not turn on their cameras for Zoom meetings out of shyness, the use of avatars in VR enabled them to ask questions. We had never observed this before in real person interactions, as the students felt that they didn’t stand out from others, mitigating their previous reticence in interacting. As such, we have decided to keep these avatars as we move forward with our VR developments.

Second, we had initially envisaged that the younger generation would be able to quickly leap into this technology without much training. Our assumption, however, proved to be false, as the set-up and training took far longer than planned for the first session. So for subsequent sessions, we needed to add additional minutes for training in the use of the headsets.

Third, not all students are able to use the VR headsets due to motion or visual issues. So having a PC version of the software provide critical to enabling these students to partake in the same session, as they were able to move onto a laptop and join others with VR headsets.

Supporting international collaboration through VR

From these initial VR developments, we also started to look at it as a platform for international collaboration. As part of the India-UK Innovation and Sustainability Chemistry Consortium (ISCC), we wanted to use VR to reduce our carbon footprint for international collaboration.10 Typical international collaborations involve in-person training and multiple scientific conferences, which all involve the release of large amounts of carbon.

Figure 3: Training room inside the ISCC VR Centre (Photo credit: UCL)

We sought to develop a VR based virtual institute… where we would be able to have live telemetry data from multiple laboratories all displayed in one central location.”

To obviate this, we sought to develop a VR based virtual institute across several floors where people would be able to meet as in real life, with conference facilities, in-person training and more importantly, where we would be able to have live telemetry data from multiple laboratories all displayed in one central location. This centre was recently realised and launched. This enables easy access to the VR based building, where members of the consortium can quickly meet in real-time and interact with each other. Crucially, we are able to provide the same advanced training to all members of the consortium as with the digitalisation of equipment therein. Anyone can receive advanced training on current state of the art equipment anywhere in the world. We are also able to host poster conferences, in exactly the same way as real life, but without the associated carbon emissions.9,10

VR: enhancing scientific training and collaboration

A VR headset now forms part of our everyday workflows… “

In conclusion, our experiences of virtual reality have been overwhelmingly positive and it has changed nearly all our approaches to scientific training and collaboration. A VR headset now forms part of our everyday workflows as we can seamlessly switch between real laboratory experiments to digital collaboration and training with anyone from any location.

Fundamentally, access to advanced scientific equipment is no longer a barrier for training as it once was. This will change global training, particularly in developing countries, as we will be able to train the next generation of global scientists using virtual reality.

One of the advantages of VR as a platform is the ability to allow for live data telemetry streams to be visualised in the virtual space. For the development of pharmaceuticals, we are looking to integrate live process data to ensure standardisation of global manufacturing. Having a VR space as a digital twin ensures that training and laboratory inductions are faster and less labour intensive. We have noticed that users who have accessed VR prior to inductions are able to operate in a safer manner far quicker than those who haven’t had the same VR pre-training. This presents an ideal opportunity to ensure safer working practices across the pharmaceutical industry.

About the authors

Dr Stephen Hilton is an Associate Professor at UCL School of Pharmacy with over 15 years’ experience in embedding new technologies into research and education. His research focuses on the applications of new technology in Pharmacy and Chemistry specialising in 3D printing and digital technologies.

Dr Blanka Szulc is a lecturer in the Division of Global and Lifelong Learning at the University of Kent and an honorary lecturer at UCL in the division of Biosciences. Blanka is the MSc programme director in the department for industrial apprentices and has been instrumental in integrating Virtual Reality into the course curriculum at Kent. In her current role, she liaises extensively with apprentices from industry across the UK where VR will be used to improve company participation and remote training.

References:

- Sarabipour S, Khan A, Seah YF, et al. Changing Scientific Meetings for the better. Nat Hum Behav. 2021; 5(3): 296–300.

- Radfar P, Bazaz SR, Mirakhorli F, et al. The role of 3D printing in the fight against covid-19 Outbreak. J 3D Print Med. 2021; 5(1): 51–60.

- Walmsley L, Hilton S, Sellier E, et al. Control and Monitoring of Temperature in 3D-Printed Circular Disk Reactors for Continuous Flow Photochemistry using Raspberry Pi Based Software. ChemRxiv Cambridge: Cambridge Open Engage. 2021.

- Penny MR, Rao ZX, Peniche BF, et al. Modular 3D printed compressed air driven continuous-flow systems for chemical synthesis. Eur J Org Chem. 2019; (23): 3783–7.

- Penny MR, Cao ZJ, Patel B, et al. Three-dimensional printing of a scalable molecular model and orbital kit for Organic Chemistry teaching and learning. J Chem Educ. 2017; 94(9): 1265–71.

- Hilton S T. Using the pandemic as a driver for innovation in research. Nat Rev Methods Primers 2. 17. [Internet]. 2022 [cited 2023Feb]. Available from: https://www.nature.com/articles/s43586-022-00106-w#article-info

- LAB427 Digital Twin. Side Quest VR. [internet]. 2022. [cited 2023Jan]. Available from: https://sidequestvr.com/app/9900/lab427-digital-twin.

- VR tech brings a UCL science lab to schools in UK and India. UCL. [internet]. 2022. [cited 2023Jan]. Available from: https://www.ucl.ac.uk/news/2022/feb/vr-tech-brings-ucl-science-lab-schools-uk-and-india.

- HPLC VR Training. Side Quest VR. [internet]. 2022. [cited 2023Jan]. Available here

- Innovation & Sustainability Chemistry Consortium. [internet]. [cited 2023Jan]. Available from: https://indouk-iscc.net/.

Related topics

Chromatography, Cleanrooms, Lab Equipment, Models, Research & Development (R&D), Virtual reality (VR)

As a company operating in the Good Manufacturing Practices (GMP) environment, we fully agree with the potential that virtual reality (VR) technology offers for improving operational processes and projects, especially those involving third-party services such as cleaning and technical services in highly regulated markets. In highly regulated industries such as GMP, where compliance with strict regulations is paramount, one of the biggest challenges is ensuring that third-party employees fully understand and comply with regulatory requirements. Clients often face issues stemming from a lack of comprehensive knowledge and awareness of GMP regulations and related obligations, and this is where VR can play a critical role. VR can be used to make third-party employees aware of the specific regulatory environment by providing them with a simulated experience that simulates real-world GMP scenarios. By immersing employees in VR training modules, they can gain a deeper understanding of GMP regulations and procedures and how they relate to their jobs.

However, an important question arises: Who should be responsible for VR instruction, the customer or the contractor?